last updated Dec 19, 1999

The goal is to characterize a fabrication process and calibrate a simulator to help a designer optimize device designs. We have a device that we want to build. First, we need to identify some basic parameters that determine the performance of this device such as geometry or shape, and material properties. Then we design test structures that isolate these parameters allowing accurate parameter extraction. All this information is stored in a detailed simulation model which can then be used to design or extrapolate the performance of the actual device.

Straightforward enough but many engineers stop at various points along the wheel. Either they perform parameter extraction without going on to the design and extrapolation step, or perform simulations without using real extracted parameters, just hoping to get lucky. All the steps must flow consistently to be confident that we know what's really going on.

Test

Structures

Fixed-fixed

beams of various lengths are fabricated. Discontinuities - steps

over POLY0, and dimples - are characterized explicitly. Buckling

amplitudes are measured using an optical profilometer. Pull-in

voltages are then measured using a CV meter. The boundary conditions

are designed to be essentially 2D to match simulations better.

Characterization

of flat beams

(table

of data)

Characterization

of beams with discontinuities

(table

of data)

Layout (GDS

II or CIF)

(click

on picture for larger image)

Composite CAD Process Definition Specification

Simulation

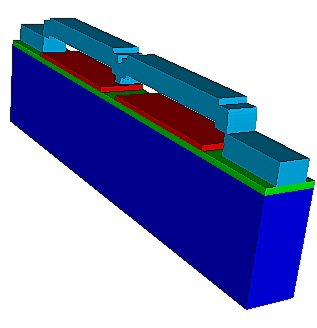

This

two-dimensional computer simulation model capturing the various

discontinuities forms a scalable simulation-based repository of

process information. Geometry and material properties than can be

passed on unambiguously to design engineers. This avoids the use of

fudge factors which are rather specific and often cryptic. An

electrostatic field subroutine that includes the effects of fringing

and finite plate thickness is incorporated into Abaqus to convert it

from a mechanical solver into an efficient coupled electromechanical

solver. Given the current state of computers and software, this is

the best tradeoff between accuracy and speed for characterization purposes.

Simulation parameters

|

Measured Thicknesses (microns) |

|

|

POLY0 (with gold) |

0.52 |

|

POLY0 (without gold) |

0.53 |

|

POLY1 |

1.97 |

|

Dimple depth |

0.67 |

|

Sacrificial PSG |

1.79 |

|

Nitride (electrical) |

0.077 |

|

Stepup sidewall |

2.10 |

|

Extracted Properties |

|

|

Initial biaxial stress |

6.3 MPa |

|

Young's modulus |

140 GPa |

Simulated beam

(Abaqus input

decks)

Extrapolation

The

well-calibrated simulation model is then used to predict the

behavior of more complex dual-electrode structures. The voltage at

one electrode required to pull the beam center onto the nitride is

measured as a function of the bias voltage applied to the other

electrode. The extrapolation is excellent confirming the validity of

the extraction procedures and the viability of these measurements as

benchmarks for coupled electromechanical simulators.

Measured

and simulated pull-in voltages

(table

of data)