last updated June 3, 1999

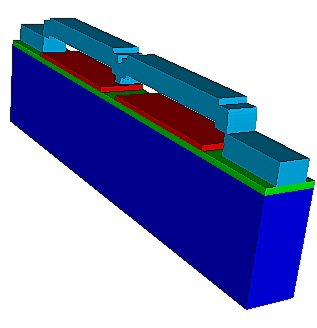

When the polysilicon beam contacts the underlying nitride layer, the system behaves like a variable capacitor that is very sensitive to contact conditions. By measuring the changes in capacitance as a function of applied voltage and time, effective surface compressibility and dielectric charging can be measured.

Measured and simulated CV curves

Dielectric

Charging

The

capacitance of the system continues to increase with time as the

voltage is held steady. This is due to charge buildup in the nitride

which increases the attractive force on the polysilicon beam. The

rate of charging corresponds to charge injection through direct tunneling.

Surface

Effects

The measured CV

curves could not be matched by simulations assuming ideal contact

conditions. A compressible surface model allows the effective gap

between the polysilicon beam and substrate to decrease with applied

voltage (and hence applied surface pressure). This compression effect

could be due to asperities or surface residue distributed over the

contact surfaces. This general behavior is verified by the CV

measurement of a flat plate where no zipping occurs yet the

capacitance still increases with voltage.

CV curve of flat plate (no zipping)